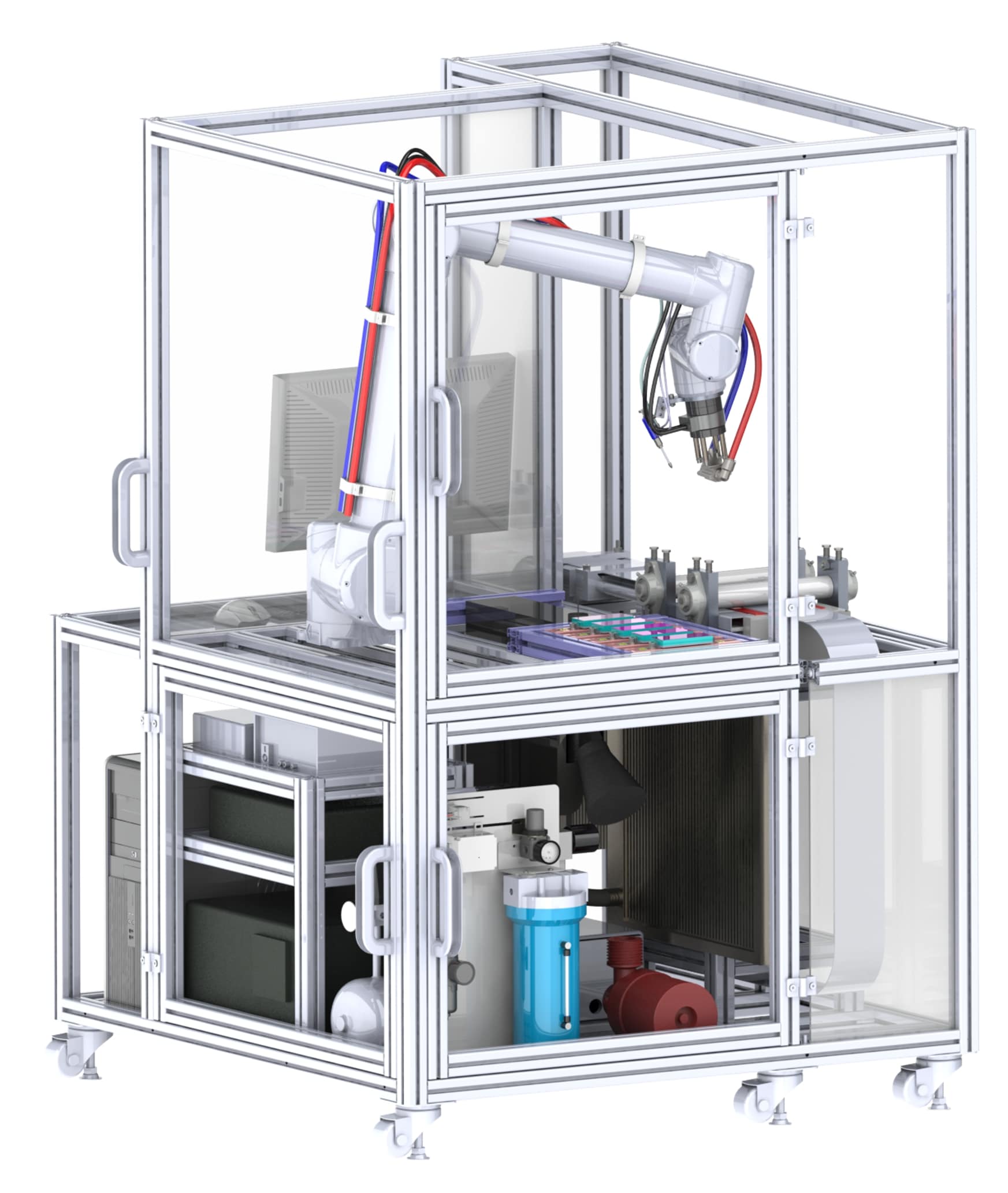

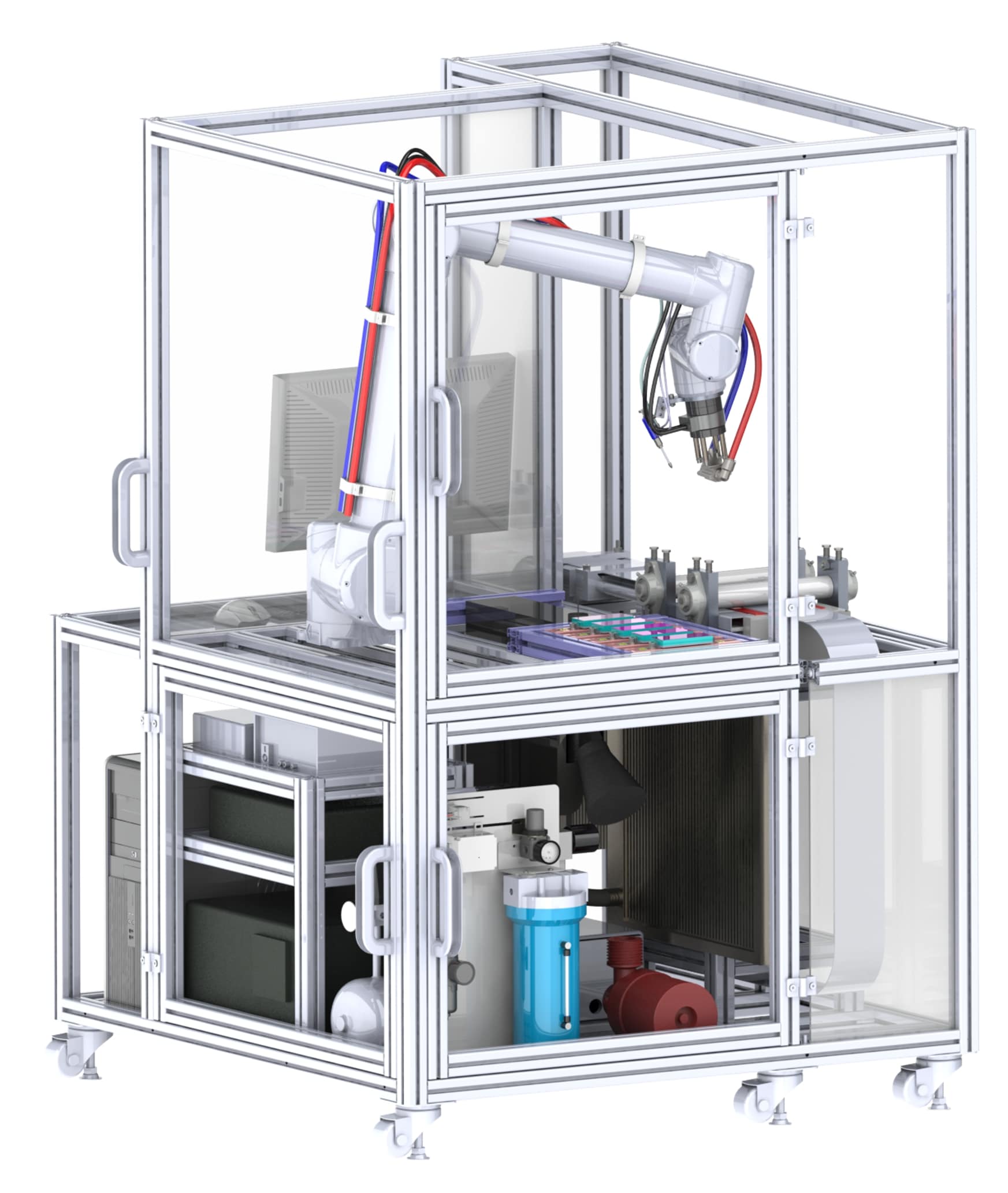

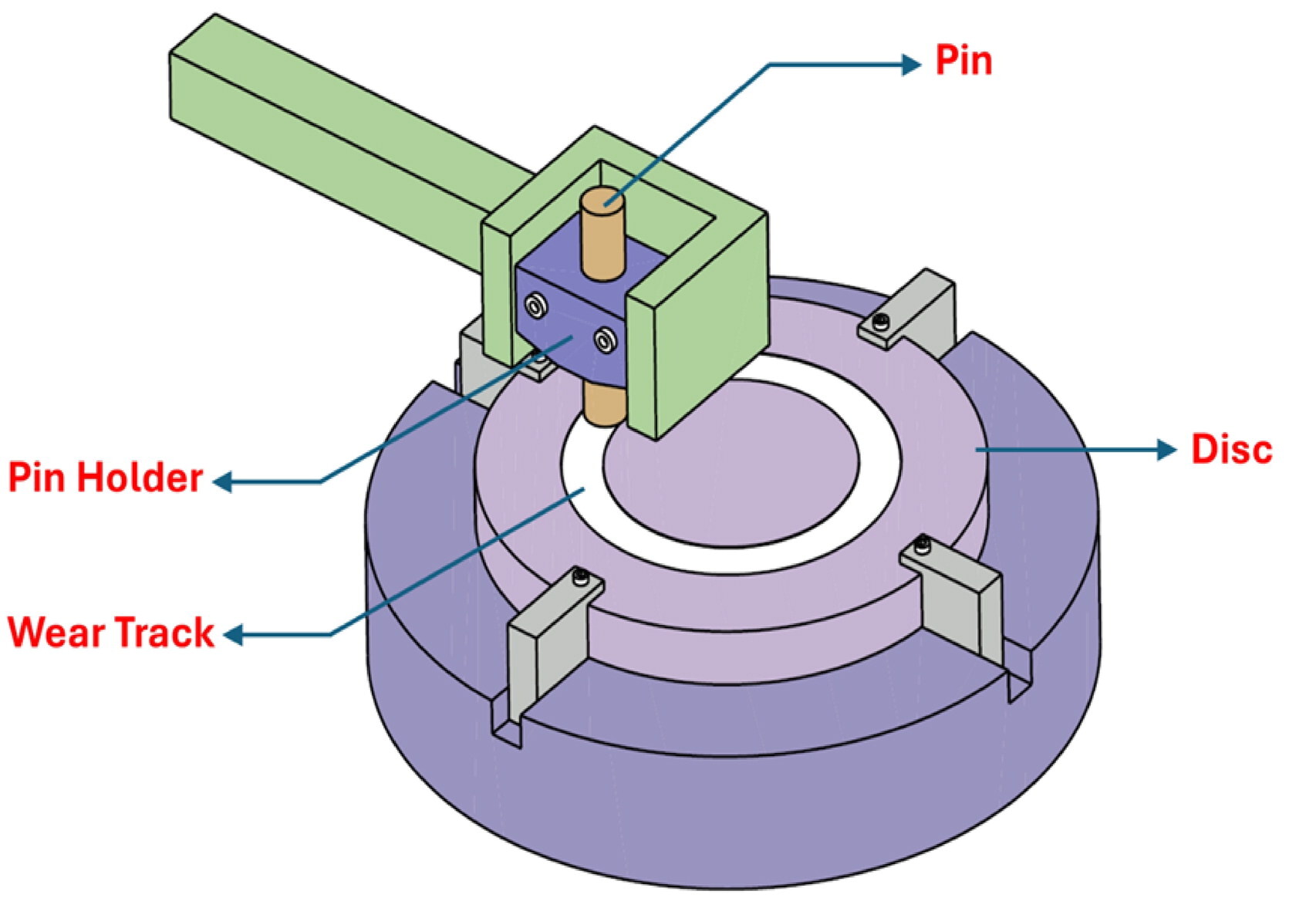

The Ultra Precise Manufacturing Process Simulator (ULTRAMAN) was developed across a Year-3 DMT, a Year-4 FYP, and continuing research to automate metal forming process simulation and test canditate lubricant, die materials, and process parameters. The aim was to combine robotics, high-temperature contact heating, automation, in-line sensing, and a local-to-cloud data pipeline to produce reproducible tests and predictive wear models.

DMT phase delivers an aluminium-extrusion frame, UR10 robotic arm and contact-heater module with shielding, filtration, and service access; thermal performance was verified.

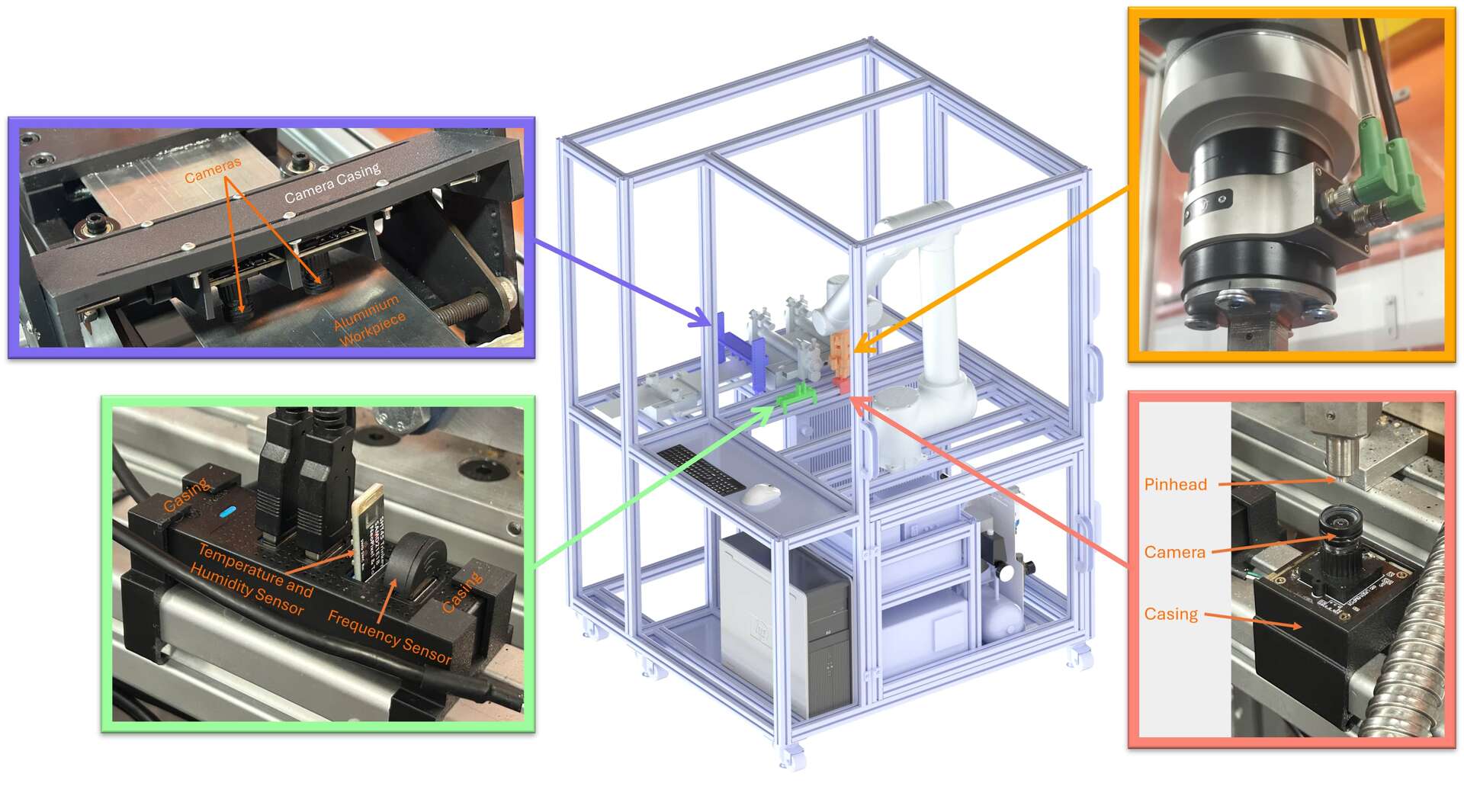

FYP integrates force, environmetal and optical sensors into autonomous operation with a local-to-cloud data path and monitoring dashboards.

Research runs comparative tests across steels, lubricants, and temperatures to characterise friction evolution, lubricant breakdown, and galling.