ULTRAMAN — Research. Ongoing work extending the platform to in-line sensing, data analysis/ML, and temperature-resolved lubricant evaluation. The goal is to show surface condition as tests run, predict galling/wear from multi-sensor data, and prevent defects via informed process and lubricant choices. We are liaising with industry partners, including Apple, Schuler and many others.

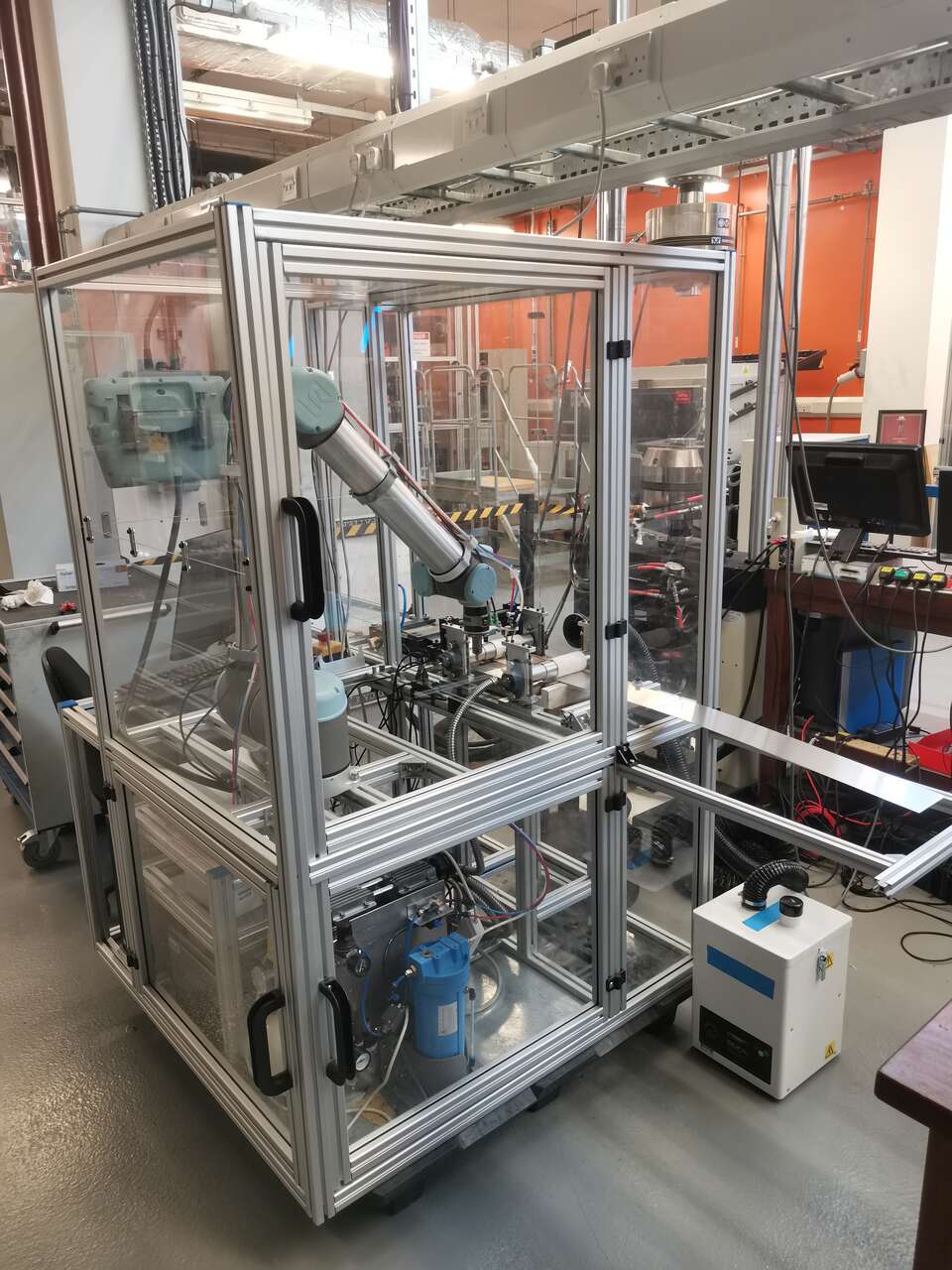

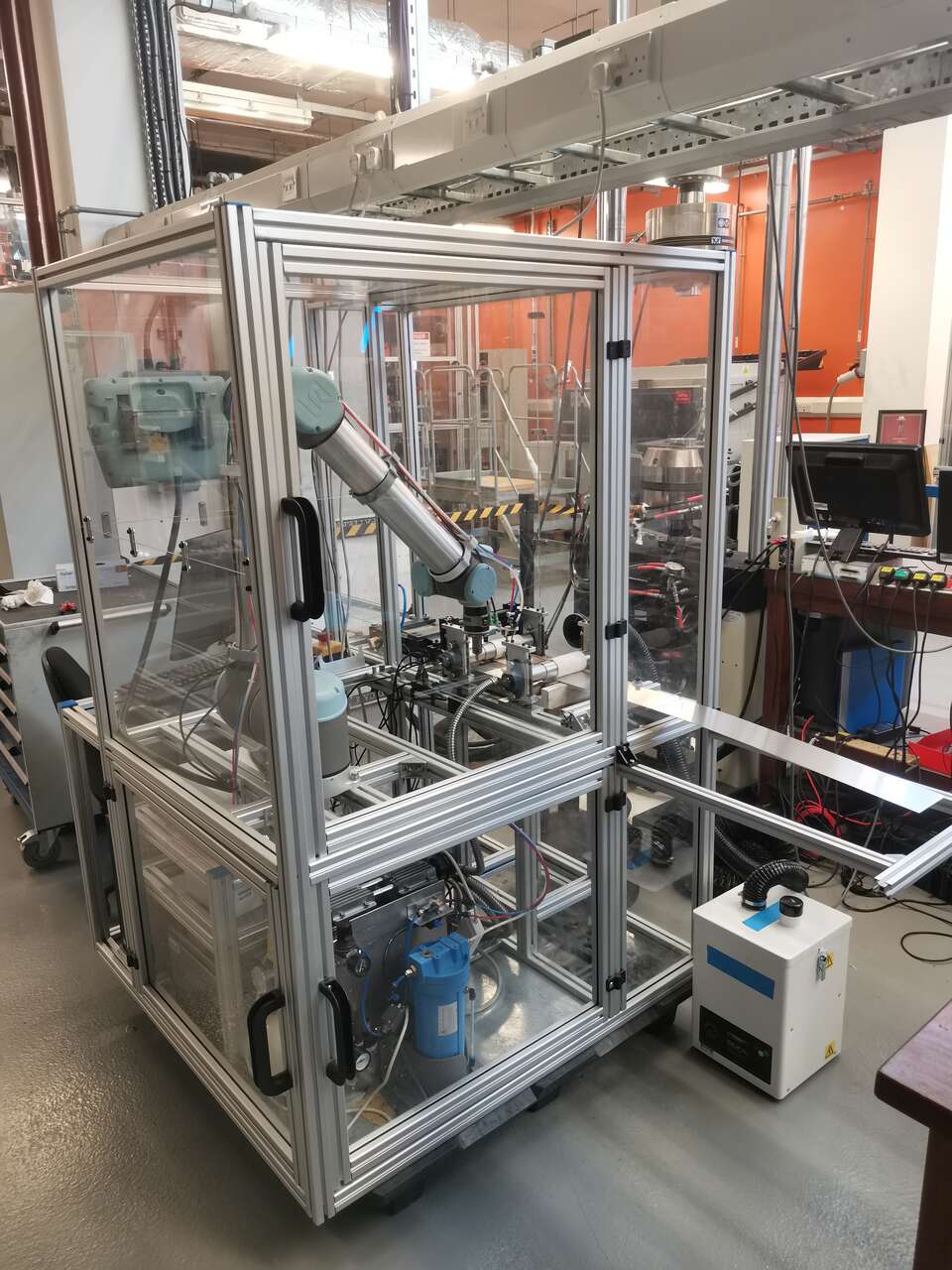

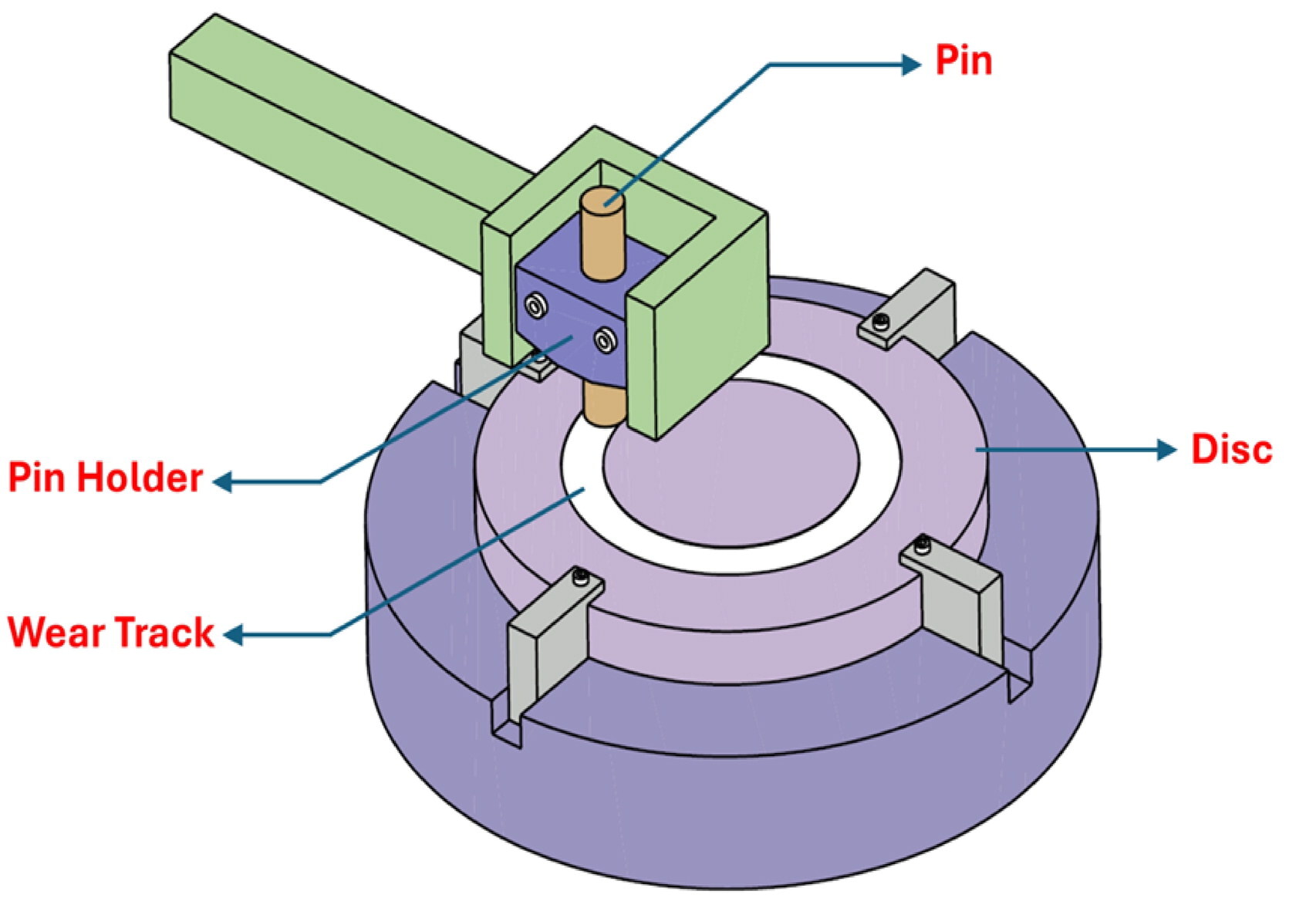

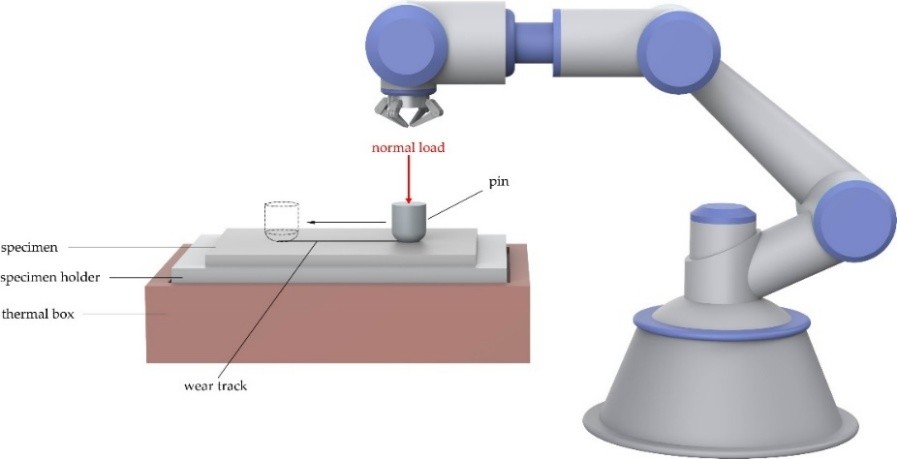

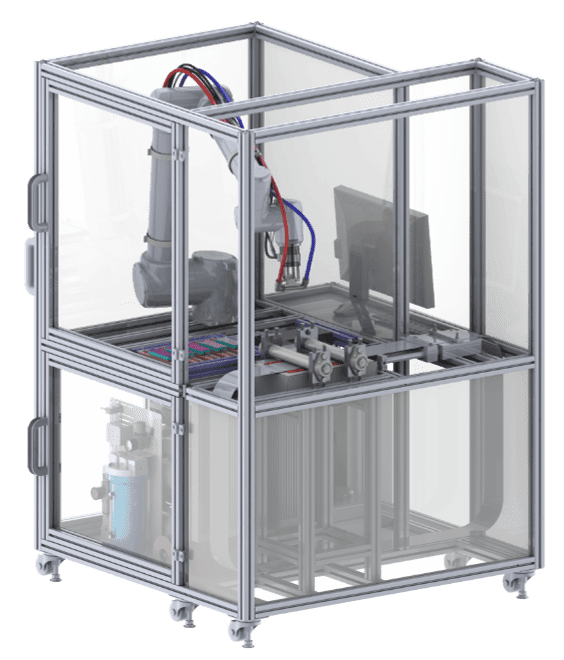

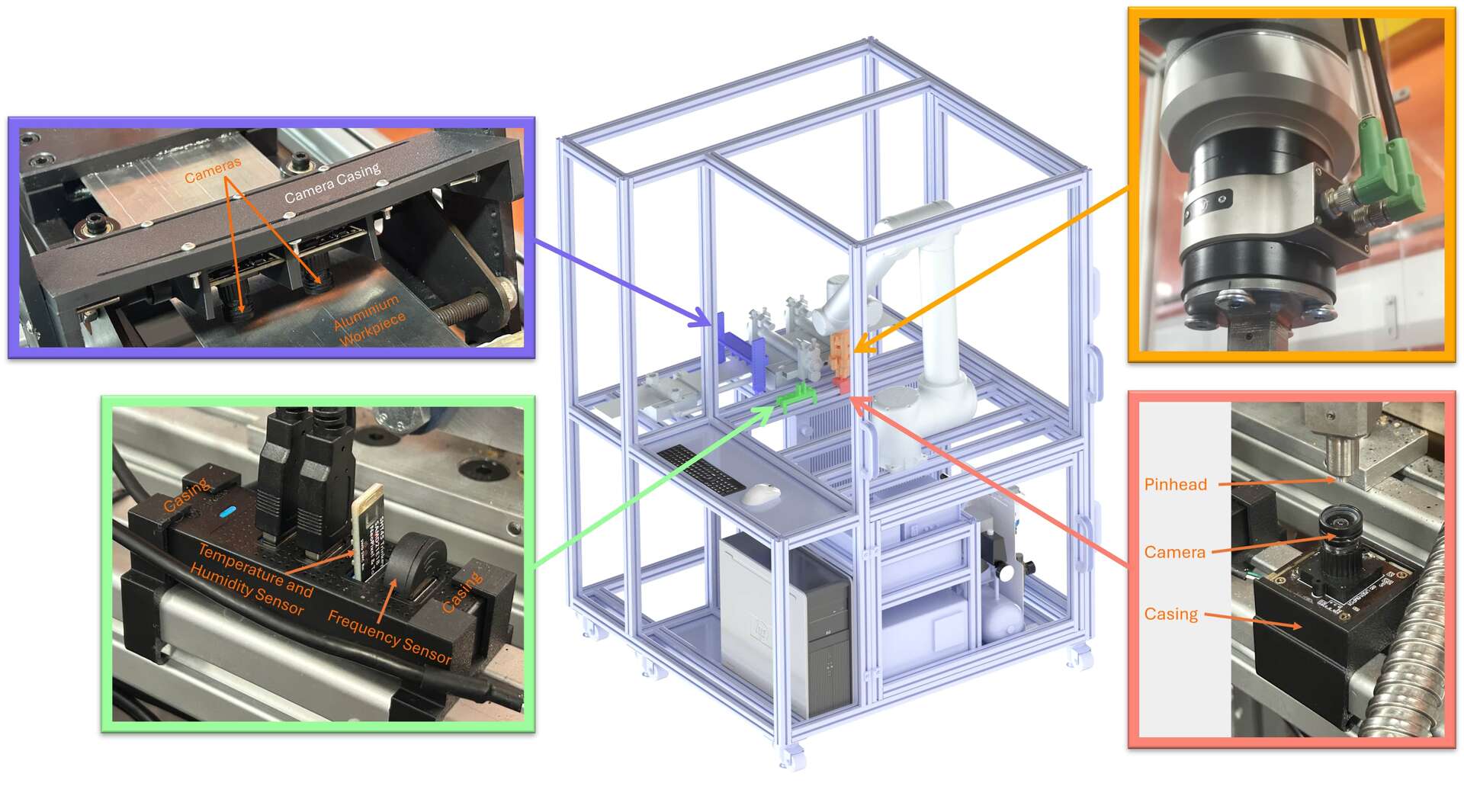

The rig uses a UR10 for repeatable loading paths, a heated contact station, and automated blank handling and spraying. Sensing includes high-resolution imaging of the wear track and pin head, force/torque, and environmental logging. Tests can run unattended for an entire shift, with data streamed to a local controller and archived in the cloud for analysis.

In-line sensing provides immediate visibility: pin-head images reveal material build-up, track images quantify width and discontinuities over cycles, and auxiliary channels (e.g., acoustics) can highlight early changes before visible damage.

Processed image metrics and friction signals are combined into a time-aligned dataset. These streams feed models that track condition and estimate the likelihood and timing of galling or rapid wear acceleration.

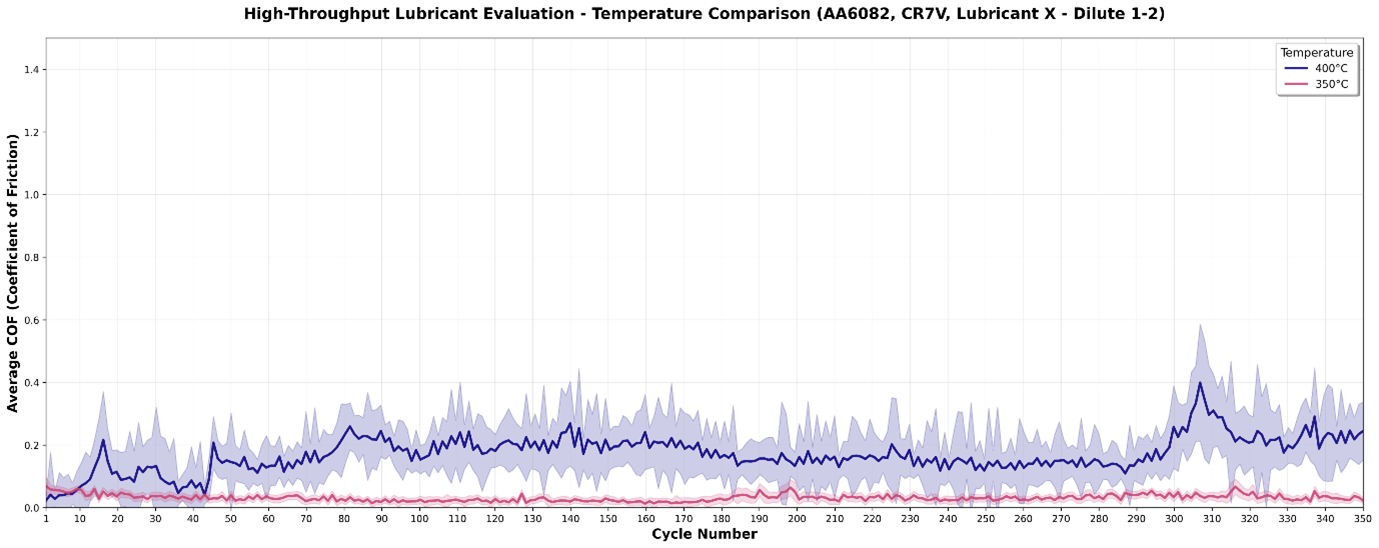

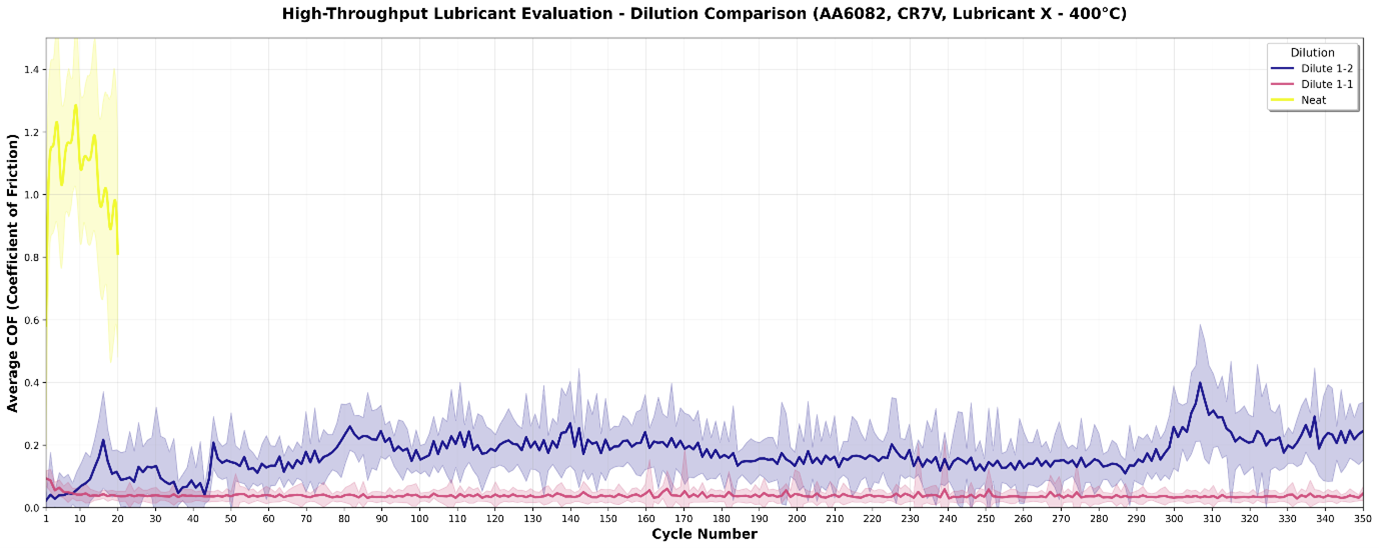

Temperature-resolved trials and controlled protocols compare anonymised lubricants and process variants. Results guide operating windows and product selection to suppress defect onset.

Current work compares several anonymised lubricants, pin head materials and process settings across controlled temperature steps and repeated runs, alongside longer continuous tests to observe degradation over hundreds of cycles. A complementary track evaluates baseline and heat-treated tool steels under the same protocols to map out material–process interactions.

Planned publications: a platform paper on the automated rig (control, sensing, data architecture) and an FYP-derived paper on multi-sensor ML for galling detection and lubricant breakdown.

Planned publications: a comparative study of tool steels and heat treatments with anonymised lubricants under controlled temperatures and dynamic protocols, and an analysis of onset/transition behaviour and wear-track evolution.

Planned upgrades include sturdier camera mounts and optics for finer track measurements, a revised sensor holder, ceramic roller service, and an access door update. Heater control is being tied directly to the PC with reliable network connectivity and thermocouple inputs for closed-loop operation.