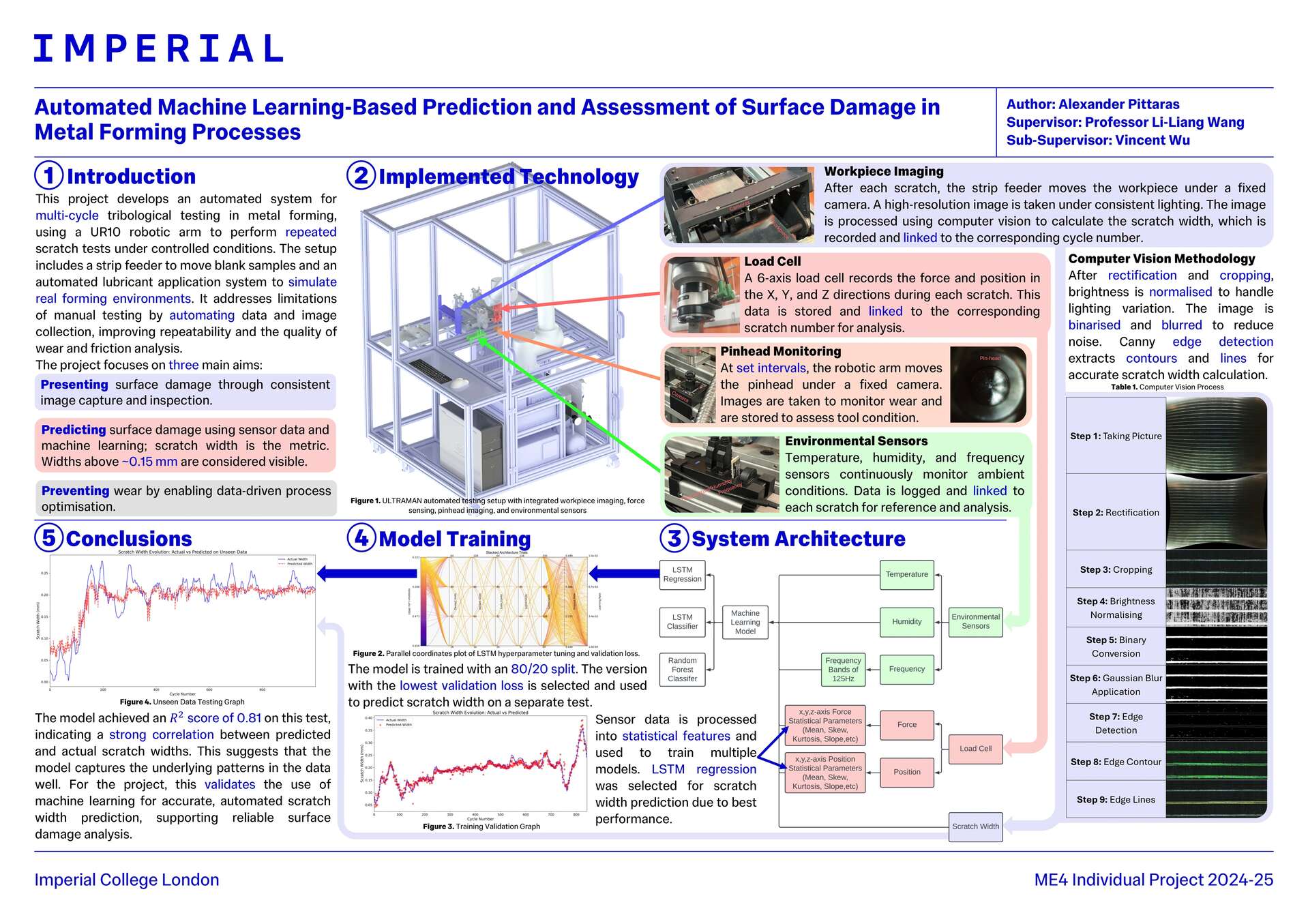

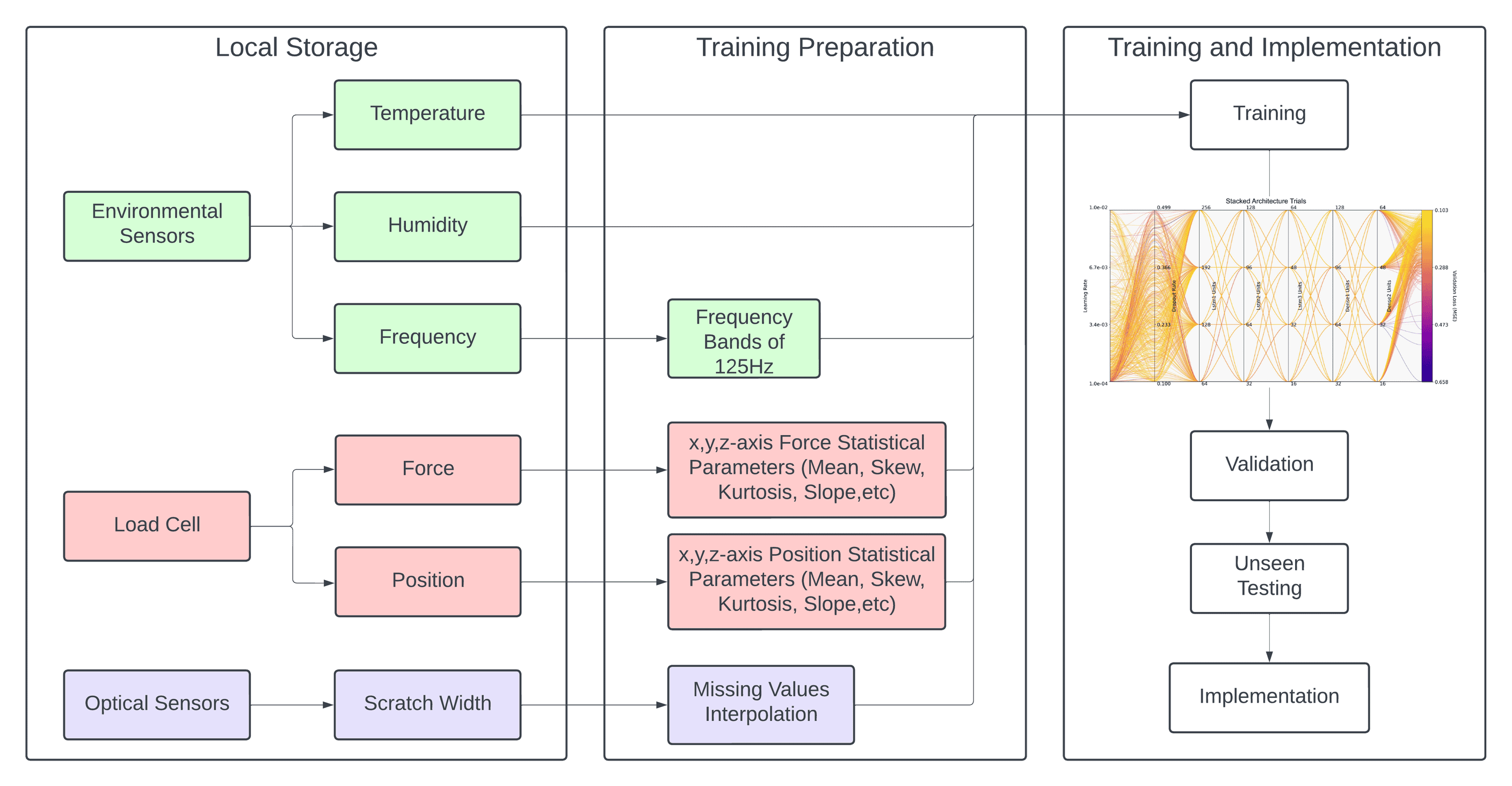

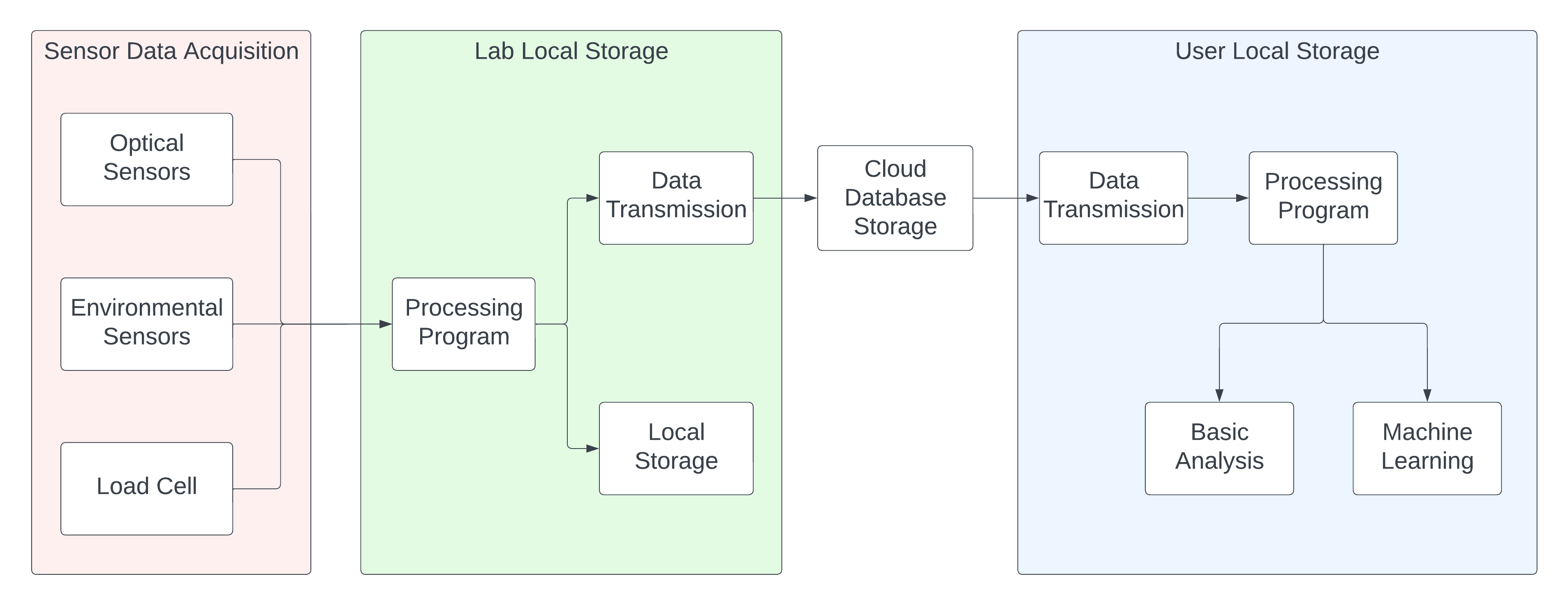

Automated ML-Based Assessment of Surface Damage in Metal Forming (MEng FYP, Year-4). I automated data capture and control on the ULTRAMAN rig, building a multi-sensor workflow and computer-vision tooling for objective wear measurement. The page below outlines the sensors, optics and CV method, key signals, Machine Learning and cloud data flow.

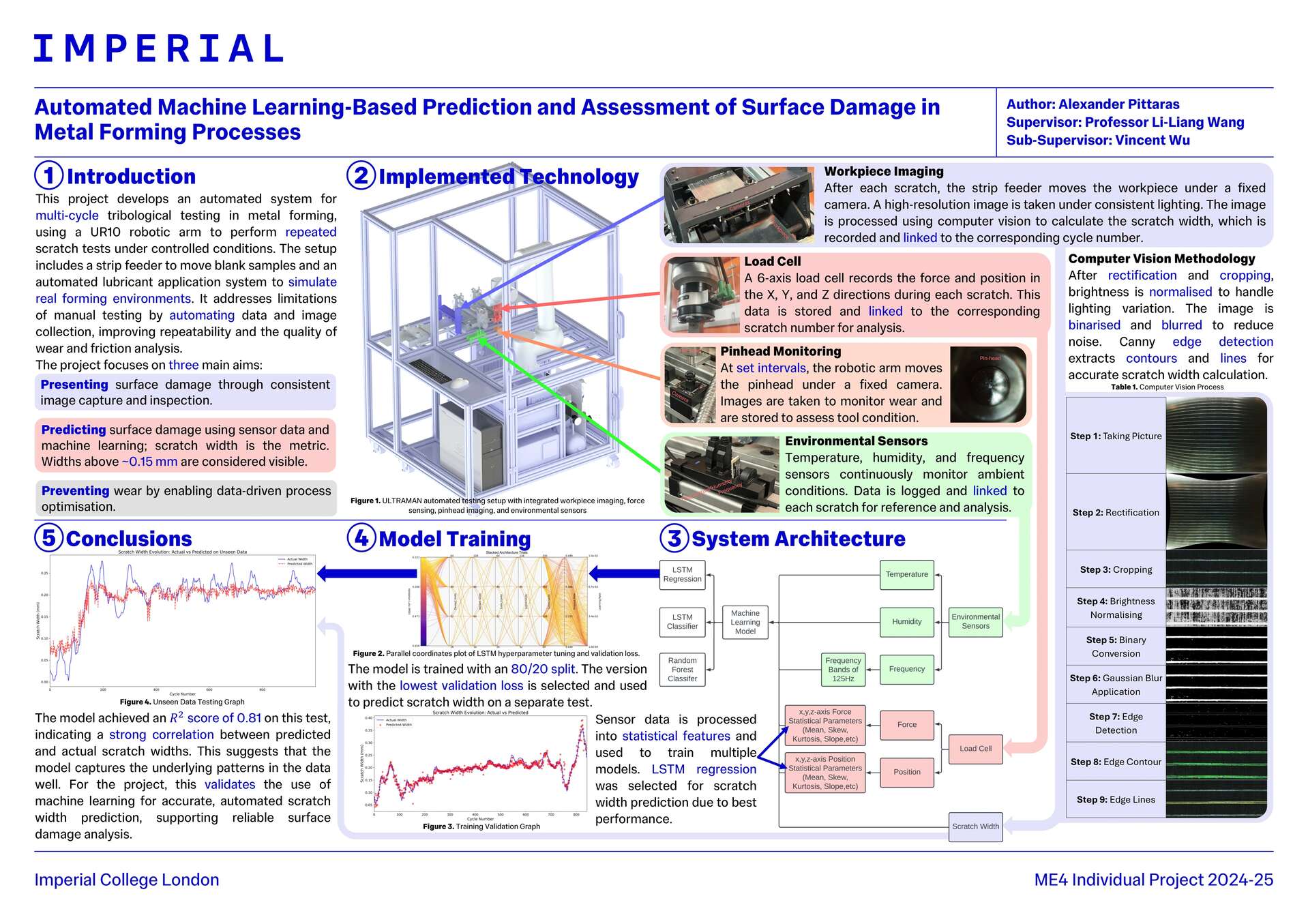

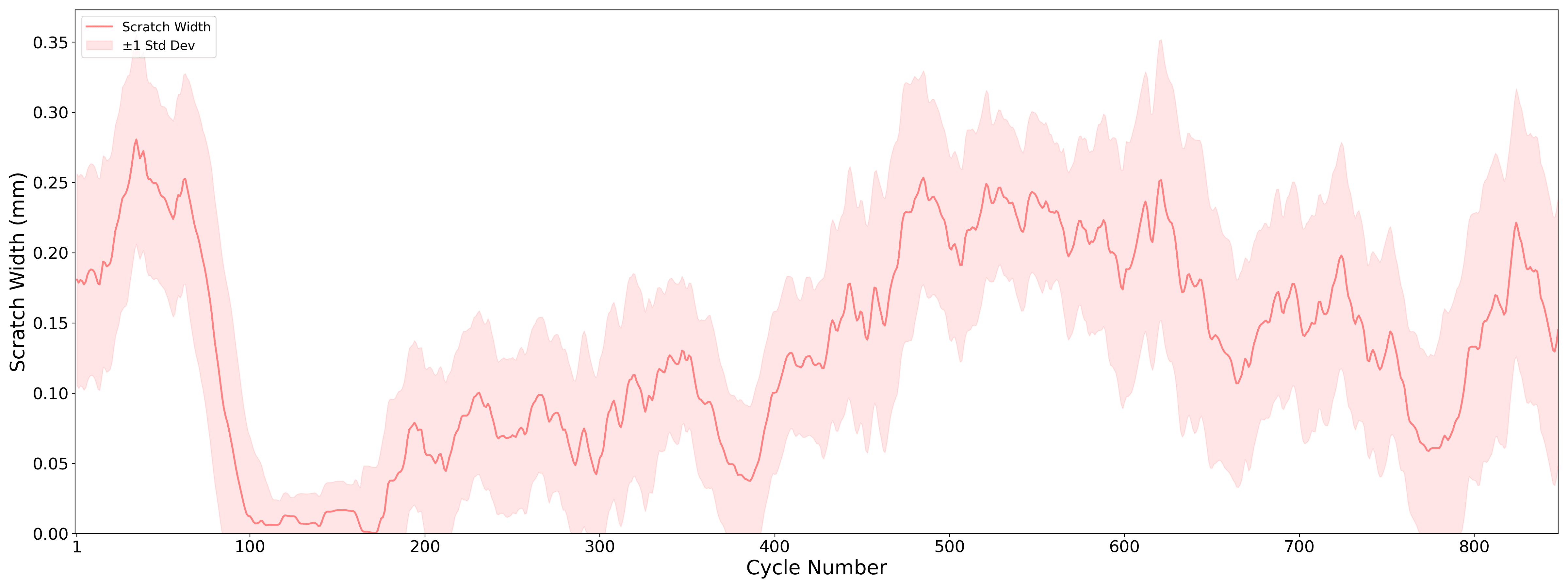

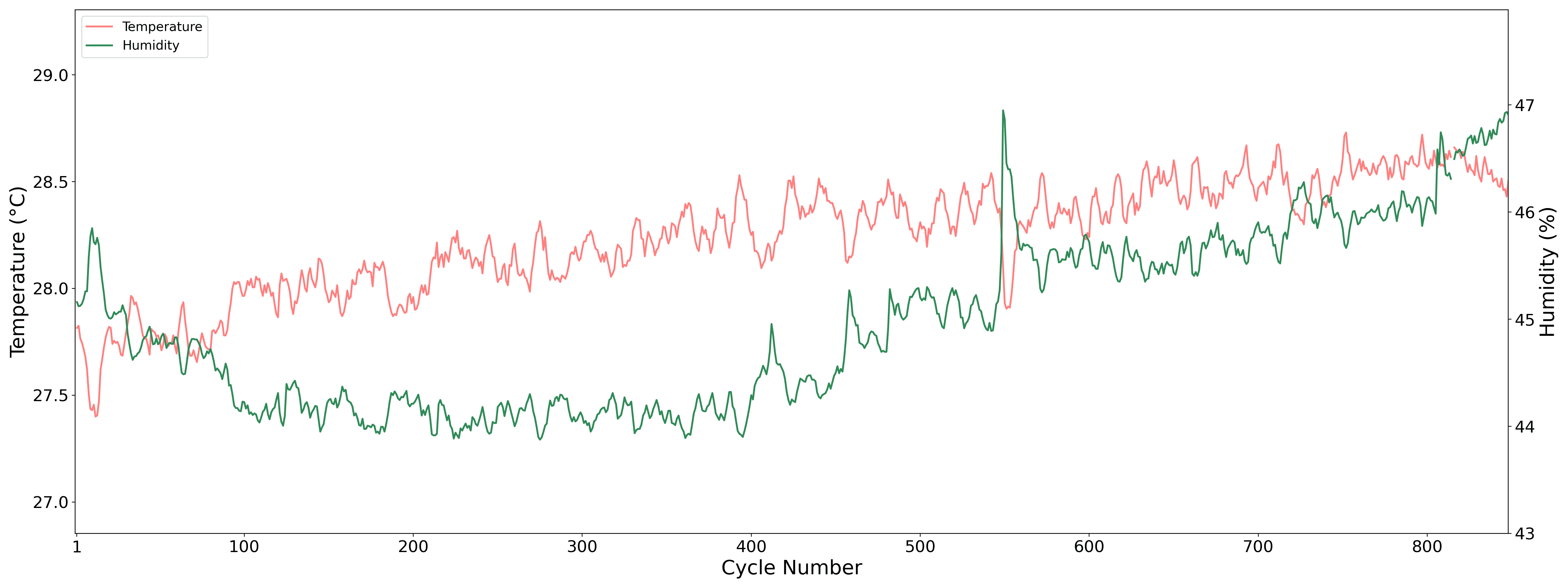

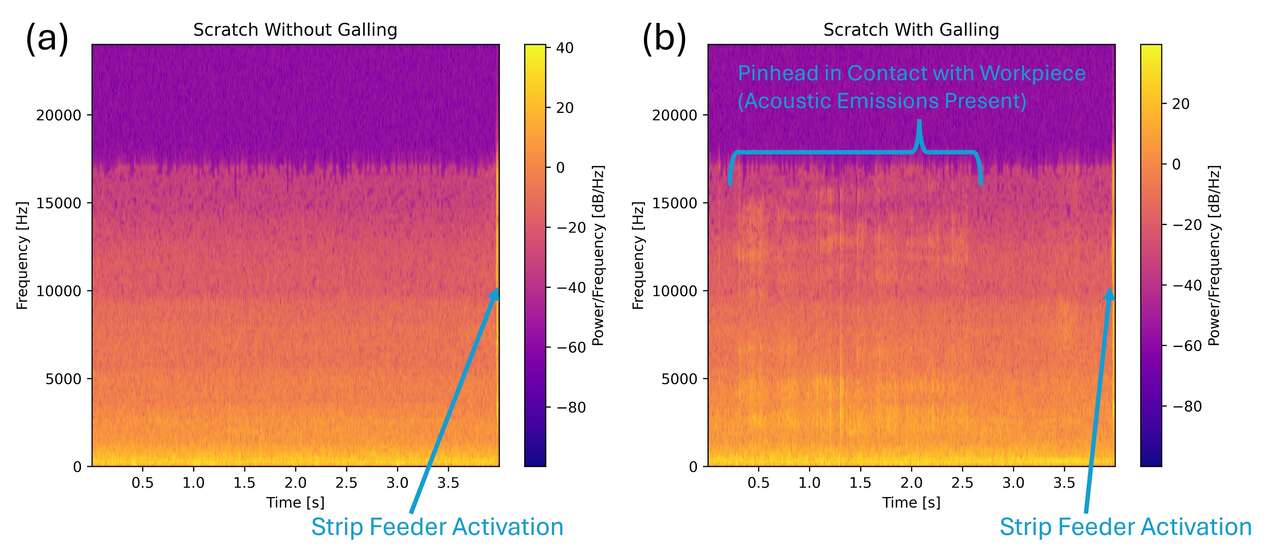

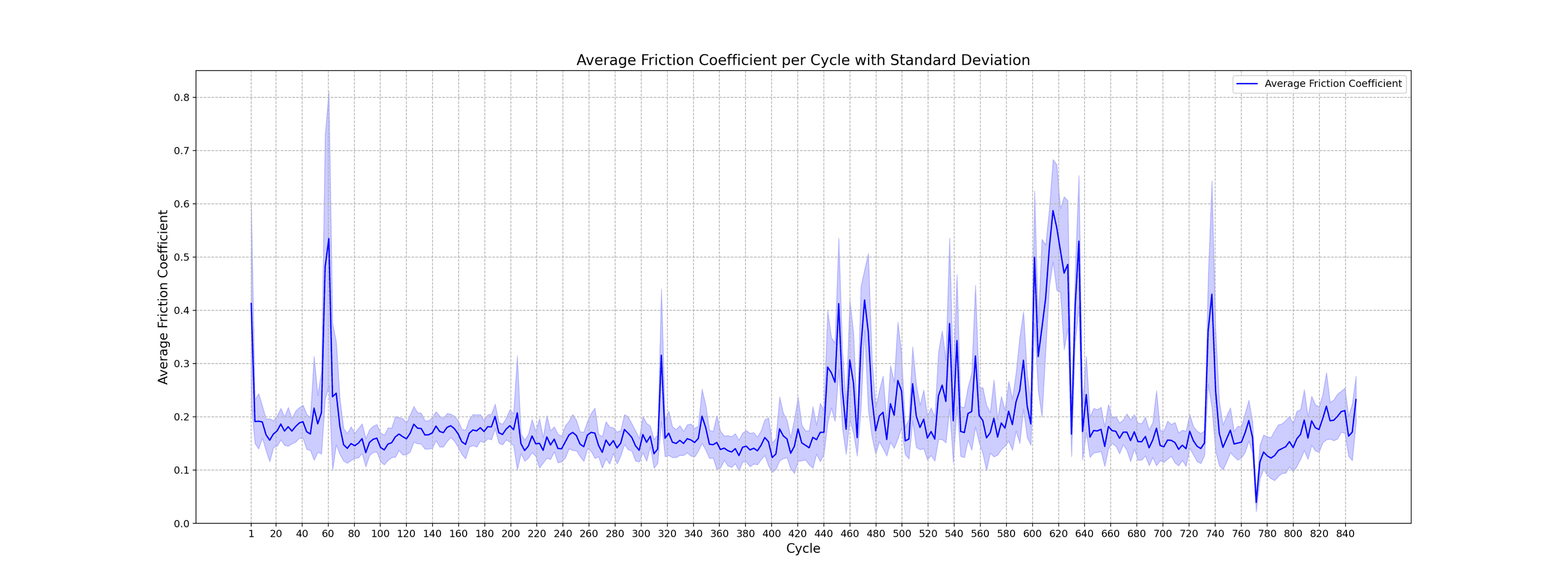

The system records time-synchronised inputs: high-resolution images of the wear track and pin head; six-axis force data; and temperature and humidity measurements. All data use a common timestamp for reproducible analysis.

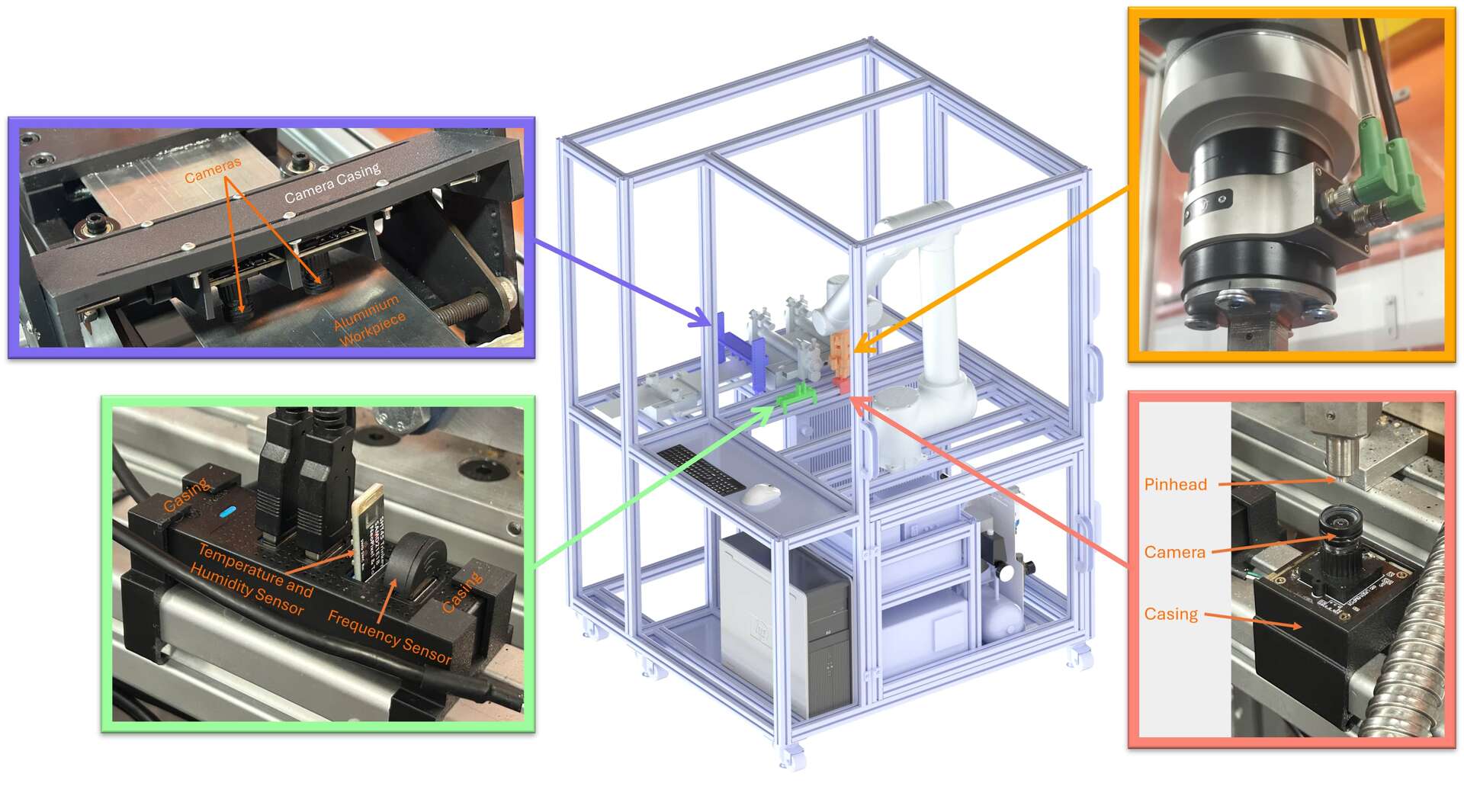

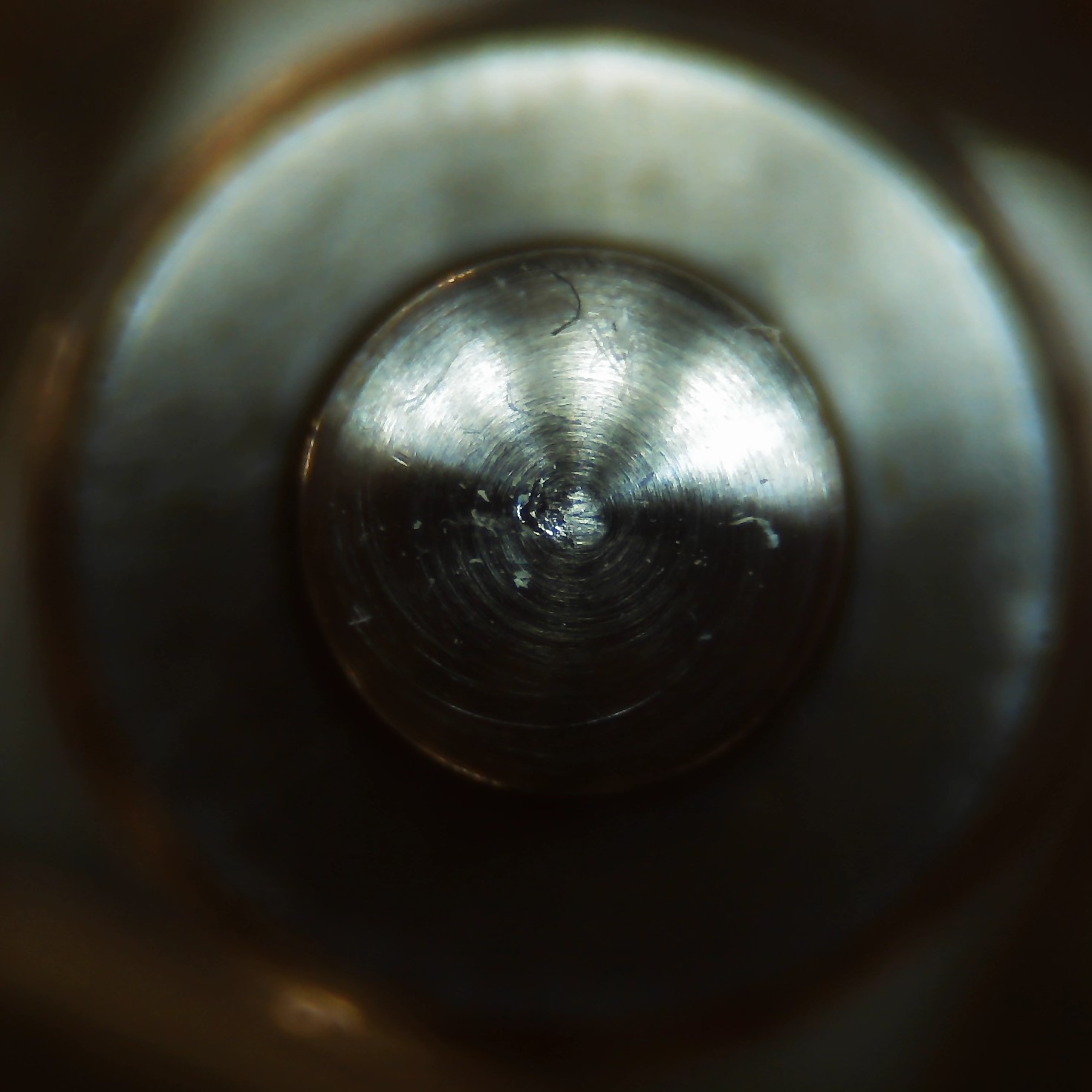

The system uses two calibrated imaging paths: a wear-track camera and a pin-head camera. The wear-track camera captures high-resolution frames with a known mm-per-pixel scale to measure width growth and surface features across cycles.

The pin-head camera records build-up and wear flats on the tool and verifies the cleaning module’s effect. Using both views separates tool effects from track damage, supports reliable labelling, and helps interpret friction and tool wear trends.

test_id, scratch_id, and timestamp; queries reconstruct runs for training and plots.