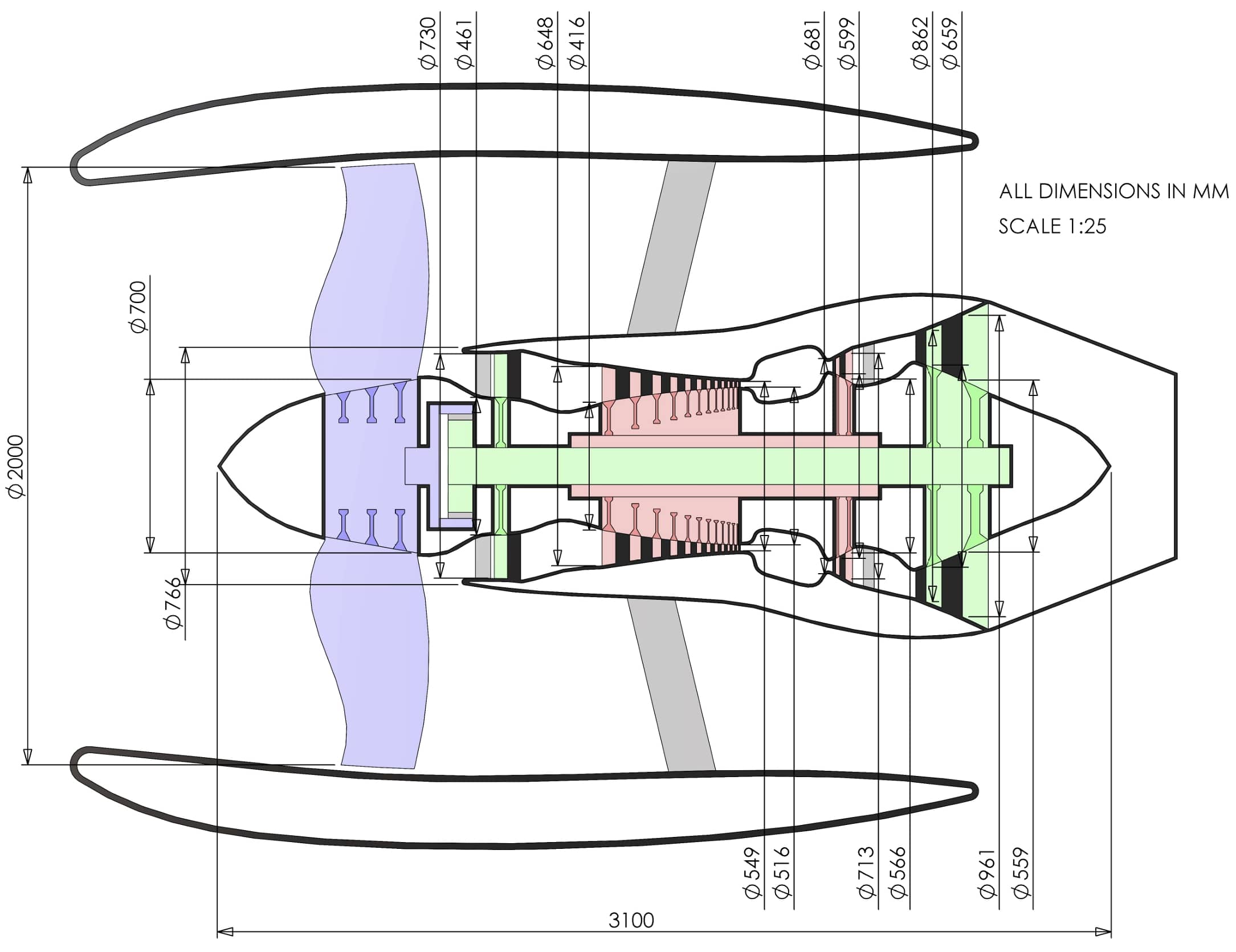

Aircraft Engine Technology — Humanitarian STOL Turbofan. Team design of a two-spool high-bypass turbofan for a relief-mission transport requiring short take-off/landing and low cruise fuel burn. The engine was sized and optimised with GasTurb, then detailed via preliminary compressor/turbine design, stress checks, and CAD.

Result: 88% (highest mark out of 15 teams).

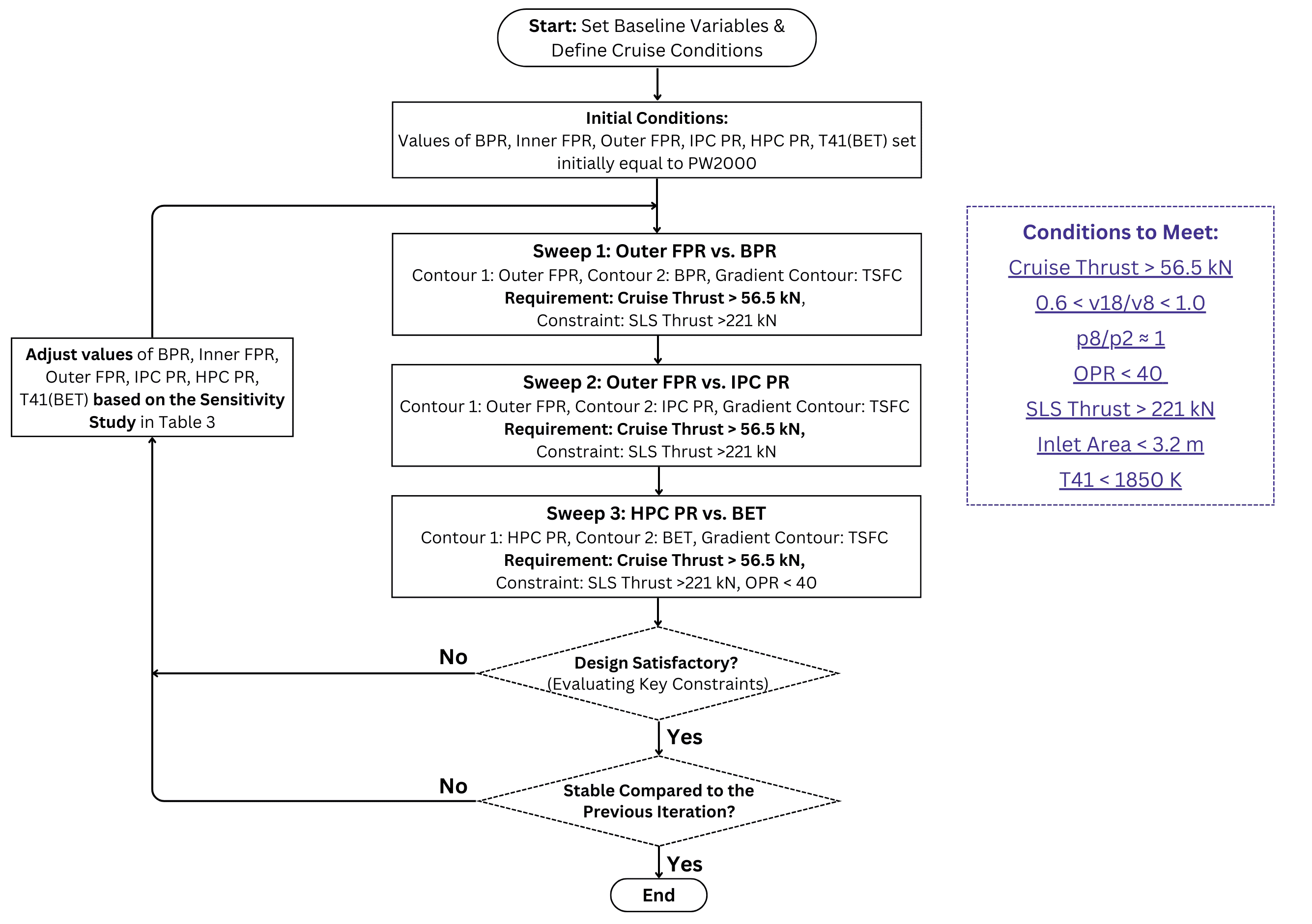

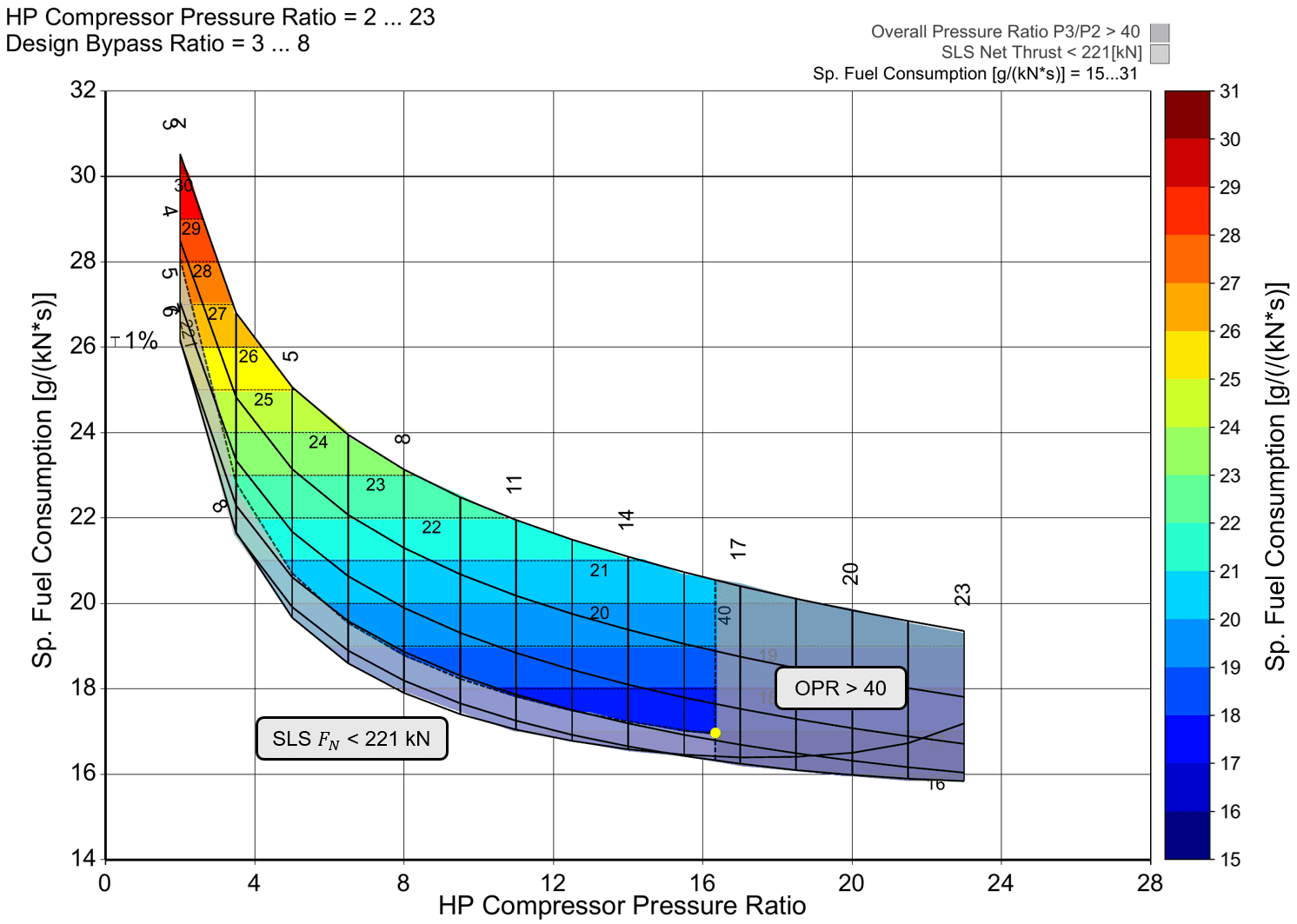

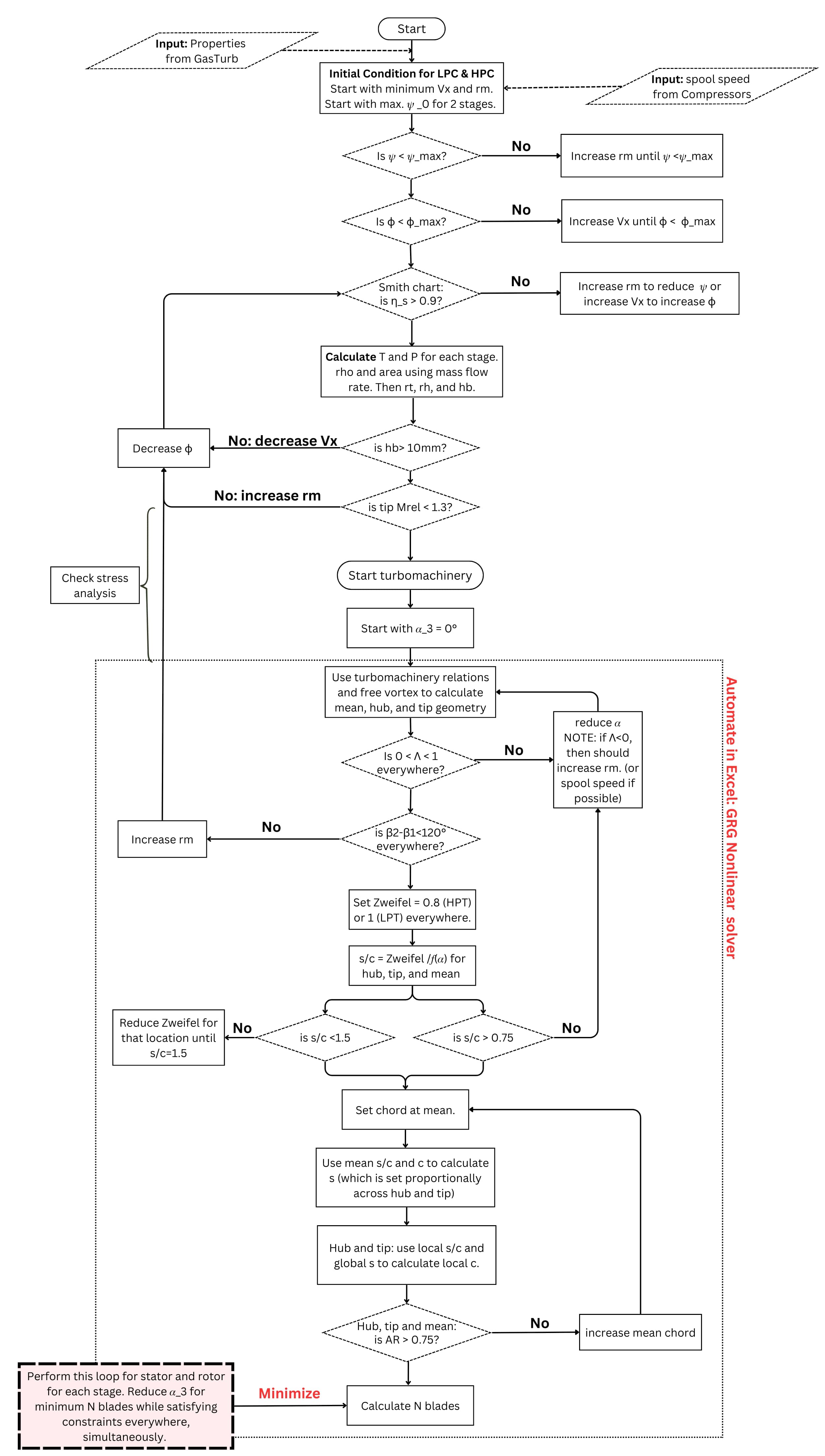

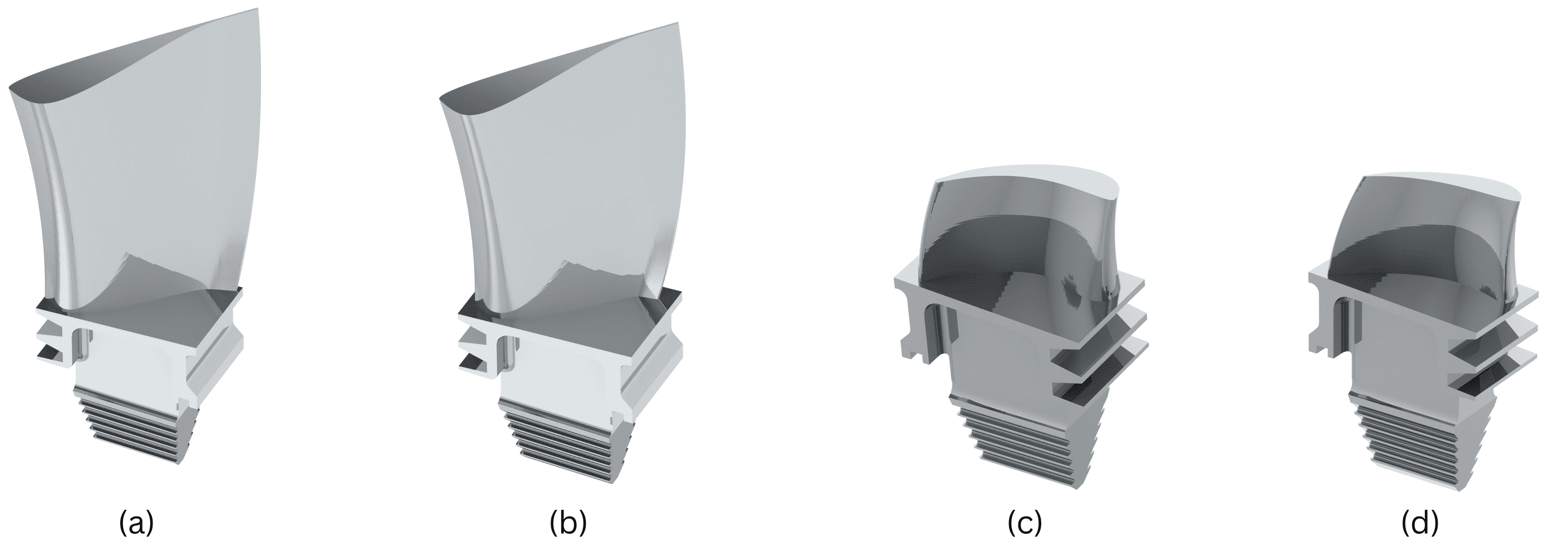

We chose a STOL-capable humanitarian aircraft and set cruise as the design point to minimise TSFC subject to off-design thrust/temperature limits. A parametric study (BPR, fan/booster split, HPC PR, mass flow, Tt4) defined a feasible space under OPR and static-thrust constraints. The final layout uses a fan+booster (LPC), multi-stage HPC, and two-stage HPT/LPT sized for cruise with margins at take-off and climb.

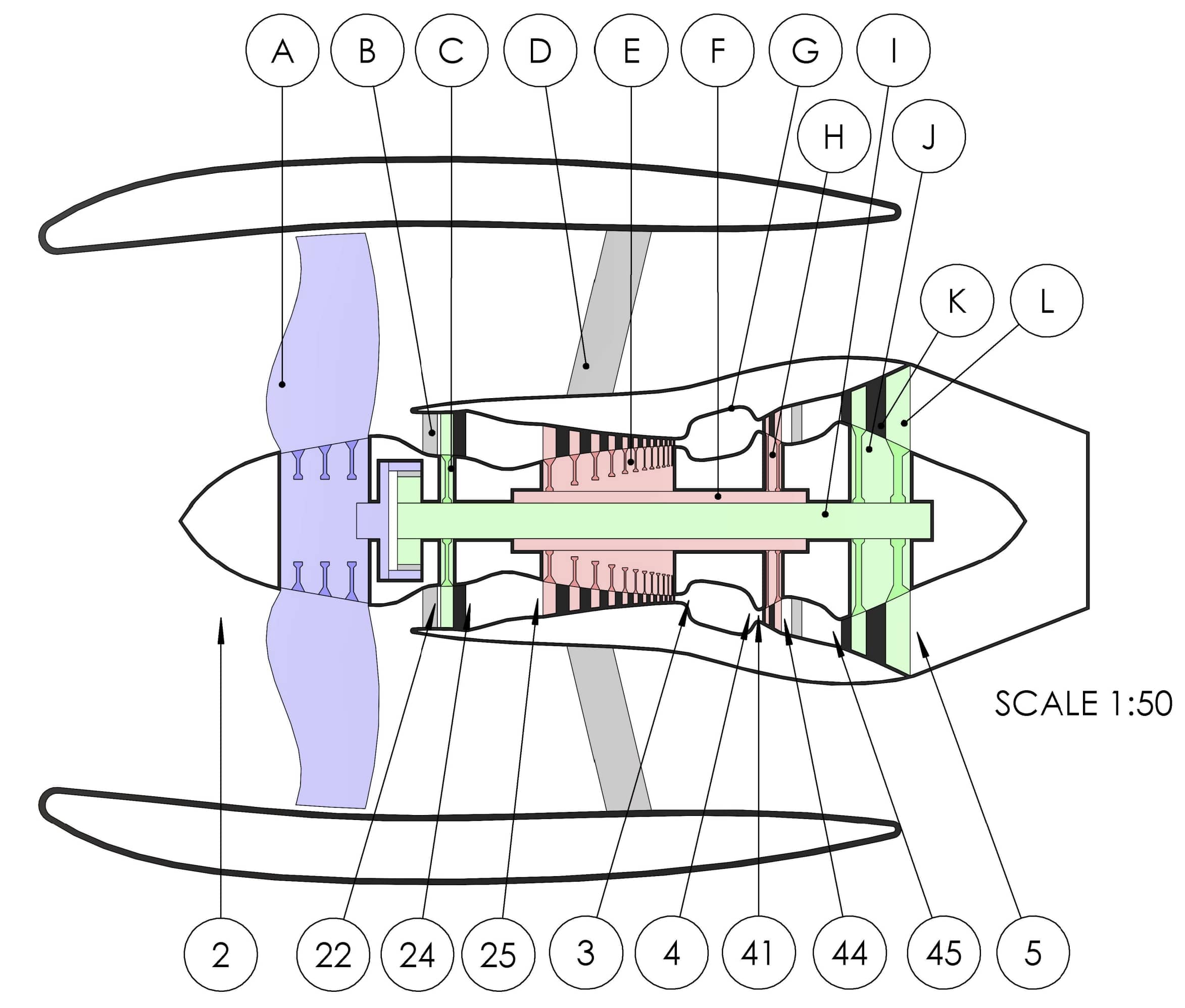

| Label | Component |

|---|---|

| A | Fan |

| B | Inlet guide vanes |

| C | Low-pressure compressor |

| D | Strut |

| E | High-pressure compressor |

| F | High-pressure spool |

| G | Combustor |

| H | High-pressure turbine |

| I | Low-pressure spool |

| J | Low-pressure turbine |

| K | Rotor |

| L | Stator |